Good Manufacturing Practice (GMP) is a program to ensure consistent production that comply food safety measures. It helps to prevent cross-contamination, adulteration, and mislabeling, resulting cut down on losses and waste, and protects both the company and consumer from negative food safety events.

GMP is a food safety assurance program that every food processor should have. It is foundation for preparing HACCP. As MeSTI, GMP compliance company gain customers' confidence more than the company that does not have. Some importers prefer to import goods from exporter that have food safety assurance program such as HACCP, GMP and MeSTI.

The followings are the GMP guidelines -

1. Quality Management

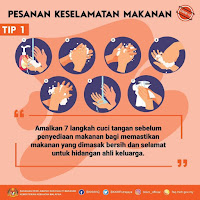

2. Sanitation & hygiene

3. Building and facilities / premises

4. Equipment

5. Raw Material

6. Personal

7. Validation and qualification

8. Complaints

9. Documentation and record keeping

10. Inspections and quality audits

These elements would be focused to set up a complete system with SOPs, control and verification. Every controls and verification would be recorded for future reference or audit purposes. Records are important so that certain issues could be traced when there is a need, such as during product recall or customer complaint. The GMP system could also be a tool for exporter / manufacturer to discuss the reason of product failure.

To apply GMP, manufacturer could apply from Food Safety and Quality department (FSQ) of Ministry of Health (MOH). After submitting application form, supporting document, GMP manuals and making payment, FSQ would do an adequacy audits (on the submitted document). When the audit is done, they will schedule a compliance audit on the manufacturer. There will be a auditors team with a lead auditor have on site and document audit.

After the audit, CARs (if there is any) would be issued to the manufacturer to comply within a period that declared by the manufacturer. When all CARs are replied, auditor would check on the reply and to discuss whether to close all CARs or request a follow-up audits. When all CARs are replied, the auditor will support the manufacturer to obtain GMP certification to MOH and the ministry will issue GMP certificate to the manufacturer.

That is not the end, MOH would schedule surveillance audit to the manufacturer once or twice a year. Thus, manufacturer should get ready all records at all time. When the controls had become a routine, the GMP system will be maintained well.

Credit:

1. Safety Culture

2. Food Quality & Safety Department, Kedah State health department.